Training Manual

JCB ECO MAX ENGINE

BASIC ENGINE TRAINING MANUAL

(ONLY FOR TRAINING PURPOSE)

CONTENTS

1. JCB ENGINE VARIENTS…..……………………………01 - 01

2. TECHNICAL DATA………………………………………..02 - 03

3. ENGINE MAINTENANCE SCHEDULE…………….04 - 04

4. SYSTEM FUNCTION…………………………………....05 - 17

5. FUEL INJECTION PUMP REMOVAL AND

REFITMENT ………………………….……………..….….18 - 24

6. VALVE CLEARANCES.…………………………….…...25 - 27

7. LUBRICATNT AND CAPACITIES…………….……..28 - 29

8. CRANKING TEST…...……………………………..…….30 - 31

9. INSTRUMENT PANEL INDICATORS……………...32 - 32

Basic description of Engine.

JCB Engine Variants

4.4 Lts Engine

• Called as the JCB 444 Engine

• 4 Cylinder, 4.4 Lts Engine

• Bore Diameter 103 mm

• Stroke Length 132 mm

• HP – 84 to 160 HP

• Powers - range of BHL (Except the 3DX), WLS,

Compactors, Tracked Excavators

4.8 Lts Engine

• Called as the JCB 448 Engine

• 4 Cylinder, 4.8 Lts Engine

• Bore Diameter 106 mm

• Stroke Length 136 mm

• HP – Only 76 HP

• Powers only the 3DX

Training Manual – JCB Eco Max Mechanical Engine. Page 1

Technical Data

Basic Engine Data

Technical Data

Basic Engine Data - 448

Engine Variants:

- DG Naturally Aspirated

- DD Turbocharged

- DF Turbocharged with Intercooler

Emission compliance Tier 3/Stage3A/Bharat Stage 3

Rated speed 2200 rpm

Weight (Dry):

- DG 472 kg (1040 lb)

-DD ` 477 kg (1052 lb)

- DF 477 kg (1052 lb)

Number of cylinders 4

Nominal bore size 106 mm (4.173 in)

Stroke 136 mm (5.316 in)

Cylinder arrangement In line

Combustion Cycle 4-stroke

Firing order 1-3-4-2

Displacement 4.80 litres

Compression ratio

- DG 18.6 : 1

- DD 18.3 : 1

- DF 17.5 : 1

Engine Compression see Note (1)

Direction of rotation (viewed from front {crankshaft pulley} end)Clockwise

Valves 4 per cylinder

Valve tip clearances (measured cold):

- Inlet 0.19 to 0.27 mm (0.007 to 0.011 in)

- Exhaust 0.56 to 0.64 mm (0.022 to 0.025in)

Lubricating oil pressure (2) 4.6 bar (67lb in2)

Combustion system Direct Injection

Fuel injection pump Rotary Mechanical

(1)Compression variance between each cylinder should be no greater than 3.5 bar (50 lb in2)

(2)Engine at normal operating temperature and maximum revs.

Technical Data

Basic Engine Data

Technical Data

Basic Engine Data - 444

Engine Variants:

- SG Naturally Aspirated

- SD Turbocharged

- SF Turbocharged with Intercooler

Emission compliance Tier 3/Stage3A/Bharat Stage 3

Rated speed 2200 rpm

Weight (Dry):

- SG 472 kg (1040 lb)

-SD ` 477 kg (1052 lb)

- SF 477 kg (1052 lb)

Number of cylinders 4

Nominal bore size 103 mm (4.055 in)

Stroke 132 mm (5.16 in)

Cylinder arrangement In line

Combustion Cycle 4-stroke

Firing order 1-3-4-2

Displacement 4.40 litres

Compression ratio

- SG 18.6 : 1

- SD 18.3 : 1

- SF 17.5 : 1

Engine Compression see Note (1)

Direction of rotation (viewed from front {crankshaft pulley} end)Clockwise

Valves 4 per cylinder

Valve tip clearances (measured cold):

- Inlet 0.19 to 0.27 mm (0.007 to 0.011 in)

- Exhaust 0.56 to 0.64 mm (0.022 to 0.025in)

Lubricating oil pressure (2) 4.6 bar (67lb in2)

Combustion system Direct Injection

Fuel injection pump Rotary Mechanical

(1)Compression variance between each cylinder should be no greater than 3.5 bar (50 lb in2)

(2)Engine at normal operating temperature and maximum revs.

ENGINE MAINTENANCE SCHEDULE

Basic description of Engine.

Engine Maintenance Schedule

SYSTEM FUNCTIONS

Basic description of Engine.

Basic Description of Engine:-

The JCB Eco max engine is a 4 cylinder diesel engine in which the fuel is ignited by compression ignition (C.I.). The

engine operates on a four stroke cycle.

The Four Stroke Cycle:

Induction

As the piston travels down the cylinder it draws filtered air at atmospheric pressure and ambient

temperature through an air filter and inlet valves into the cylinder.

Compression

When the piston reaches the bottom of its stroke the inlet valves close. The piston then starts to rise up the

cylinder compressing the air trapped in the cylinder. This causes the temperature and pressure of the air to rise. Fuel

is injected into the cylinder when the piston is near to top dead centre.

Power

The piston continues to rise after the start of fuel injection causing a further increase in pressure and

temperature. The temperature rises to a point at which the fuel/air mixture ignites. A cylinder is said to be `firing' when

the fuel/air mixture ignites. This combustion causes a very rapid rise in both temperature and pressure. The high

pressure generated propels the piston downward turning the crankshaft and producing energy.

Training Manual – JCB Eco Max Mechanical Engine. Page 5

SYSTEM FUNCTIONS

Basic description of Engine.

Exhaust

Once the piston has reached the bottom of its travel, the exhaust valves open and momentum stored in the flywheel forces the piston up the cylinder expelling the exhaust gases. In a running engine these four phases are continuously repeated. Each stroke is half a revolution of the crankshaft, thus, in one cycle of a four stroke engine, the crankshaft revolves twice.

SYSTEM FUNCTIONS

Basic description of Engine.

The engine is started by electric starter motor. The motor turns the engine via a pinion and teeth on the engine

flywheel. When the engine runs the crankshaft drives the camshaft via gears. The camshaft opens and closes the inlet and

exhausts valves and via pushes rods in time with the four stroke cycle. The engine has 16 valves, 2 inlet and 2 exhaust valves for

each cylinder.

The crankshaft also drives a mechanical fuel injection pump via gears. The pump injects fuel via injectors, or atomisers

into each cylinder in time with the four stroke cycle. Fuel is pumped from a fuel tank to the injection pump by means of a lift

pump driven by cam lobes on the camshaft.

Air is drawn into the engine via inlet manifold and exhaust gasses exit via exhaust manifold. On turbocharged engines

an exhaust driven turbocharger pressurises air at the inlet manifold.

A mechanical lubrication oil pump is driven by the crankshaft via gears. The pump pressurises and circulates oil for

engine lubrication and cooling purposes. A drive belt again driven by the crankshaft drives a coolant circulation pump,

alternator, radiator cooling fan and other ancillaries such as an air conditioning compressor.

Camshaft and Valve Operation:

As the crankshaft rotates the camshaft also rotates, driven by a gear on the crankshaft. The inlet and exhaust valves

are opened by lobes on the camshaft in time with the cycle. The diagrams show the position of the camshaft at each part of the

four stroke cycle. It can be seen that for a complete cycle the camshaft revolves once. Since the crankshaft revolves twice

during the cycle it follows that the camshaft is driven at half crankshaft (engine) speed.

Four Cylinder Cycle

With the crankshaft positioned as shown the pistons in numbers 1 and 4 cylinders are at top dead centre and pistons

in numbers 2 and 3 cylinders are at bottom dead centre.

Cylinder Number 1 - The piston is at the top of its Compression stroke and is about to start its Power stroke -Valve

Operation Inlet and exhaust valves closed

Cylinder Number 2 - The piston is at the bottom of its Power stroke and is about to start its Exhaust stroke - Valve

Operation Inlet valves closed exhaust valves about to open

Cylinder Number 3 - The piston is at the bottom of its Induction stroke and is about to start its Compression stroke.

Valve Operation Exhaust valves closed, inlet valves about to close

Cylinder Number 4 - The piston is at the top of its Exhaust stroke and is about to start its Induction stroke. Valve

Operation Exhaust valves about to close, inlet valves about to open

Firing Order

A cylinder is said to be `firing' when the fuel/air mixture ignites and the piston is about to start its power stroke.

It is important to note that number 1 cylinder is `firing' and about to start its Power stroke. Rotating the crankshaft a

further 360 degrees would position the pistons as described but the engine would be at a different stage in its four stroke cycle,

with number 1 cylinder about to start its Induction stroke.

The stages in the four stroke cycle for each cylinder are as follows:

SYSTEM FUNCTIONS

Basic description of Engine.

Timing Gears

The timing gears are located inside a casing at the flywheel end of the engine.

The engine must be `timed' so that the camshaft operates the valves and the fuel injection pump injects the fuel at

the correct times relative to the crankshaft position. Valve timing is achieved by ensuring that the camshaft drive gear B is

meshed to the crankshaft gear A at their correct angular positions, for more information about valve timing. Timing of the fuel

injection pump is not dependent on drive gear meshing. The pump drive shaft is supplied locked at the correct angular position

relative to crankshaft/camshaft position. With the crank and camshaft positioned correctly (using temporary locking pins), the

pump is fitted to drive gear and its drive shaft unlocked.

All the gears are driven via the crankshaft gear.

Camshaft gear - The camshaft is driven at half crankshaft speed.

Fuel injection pump gear - The fuel injection pump is driven via compound gear fitted to the camshaft. The pump

rotates at half crankshaft speed.

Training Manual – JCB Eco Max Mechanical Engine. Page 8

SYSTEM FUNCTIONS

Basic description of Engine.

Oil pump gear -The lubrication oil pump is driven directly by the crankshaft gear.

Heavy Duty PTO Gear (if fitted). The PTO is driven by the crankshaft gear via idler gear (if fitted). The PTO is driven

by the camshaft gear.

Valve Train

The valve train system opens and closes the valves with correct timing in relation to the piston movements.

The camshaft drive gear is driven by the crankshaft gear at half the speed of the crankshaft. Camshaft lobes, two for

each cylinder, (operating exhaust and inlet valves) actuate the valve tappets.

Each push rod has one end in a valve tappet and the other end under a rocker arm, or as applicable. Adjusting screw

has a ball shaped end that locates in the push rod.

The adjusting screw is used for setting the valve clearance.

When the camshaft rotates the cam lobes act on the tappets. The push rods act on the rockers which pivot on shaft,

depressing two valves at once via the bridge piece.

The screw is self locking in the rocker by means of a tapered thread. Wave washers act like springs to keep the

rockers in their correct positions along the shaft and prevent them contacting one another. The rockers incorporate a swivel tip,

ensuring alignment with the bridge piece. This prevents excessive wear.

Each valve has a compression spring. The function of the spring is to close the valve and at the same time return the

rocker arm and push rod ensuring that the tappets follow the camshaft lobes. The spring is located on the valve stem by a

retainer and split collets.

The valves extend through the cylinder head. There are no sleeves or

valve guides in the cylinder head. The valves are made from a special metal to

provide a long service life. Damaged or worn valves cannot be lapped or re-

ground and must be replaced with new ones. Each valve stem has an oil seal.

Valve seat inserts are pressed into the cylinder head. The seat inserts

are also made from a special metal to provide for a long service life. Damaged or

worn seat inserts can be removed and replaced with new ones.

Lubrication System

Basic Description

The lubrication system distributes oil around the engine by a system of galleries and drillings in the cylinder block and

cylinder head. The oil lubricates and seals the moving parts of the engine, reducing friction and wear. In addition the oil plays an

Training Manual – JCB Eco Max Mechanical Engine. Page 9

SYSTEM FUNCTIONS

Basic description of Engine.

important role in cooling the engine by carrying heat from the engine to the cooler. A piston cooling jet sprays oil onto the

underside of the pistons to keep them cool.

Oil is drawn from the oil pan (sump) by the integral oil pump via the strainer. The strainer prevents any large particles

of debris passing through, which may damage the pump.

The oil passes from the outlet side of the pump through a relief valve which limits the maximum oil pressure by

venting oil back to the inlet side of the pump.

From the pump the oil passes through the cooler and filter. After cooling and filtering, oil passes into the main oil

gallery. An oil pressure switch senses oil pressure. From the main gallery oil is delivered, via drillings, to the crankshaft main

bearings, rocker assembly, and camshaft and timing gears. Note that drilling is through the cylinder block and cylinder head.

When the high pressure oil has passed through the bearings it reverts to sump pressure and `splash' lubricates

internal components such as rocker tips, cam lobes and timing gear teeth. Gravity drains the oil via galleries in the cylinder head

and block, back into the oil pan (sump). A drain slot allows oil to drain from the timing case back to the oil pan.

1. Oil pan (sump)

2. Suction strainer

3. Oil pump 4 Oil cooler

5. Filter

6 .Camshaft - high pressure oil feed

7. Crankshaft main bearings - high pressure oil feed

8 .Rocker assembly - high pressure oil feed

9. PTO idler gear bearing/timing case - high pressure oil feed

10. External high pressure oil feed connection (engine block) - Turbo charger (if fitted)

11. Main high pressure oil feed gallery (engine block)

Training Manual – JCB Eco Max Mechanical Engine. Page 10

SYSTEM FUNCTIONS

Basic description of Engine.

Color Key - Lub Lines

Green Oil at sump pressure

Red Oil at high pressure

Pink Oil at lower pressure but higher than sump pressure

Fuel System

Basic Description

The fuel system is central to the performance and efficiency of the engine distributing an accurate amount of fuel to

each cylinder at exactly the right time.

Fuel is drawn from the tank by engine driven lift pump via the water trap. The trap separates any water in the fuel

before if passes through the lift pump.

Fuel is pressurised at low pressure by the lift pump and passes through a fuel filter on its way to the inlet on the fuel

injection pump. Effective filtration and decontamination of the fuel is essential. The injection pump can be damaged beyond

repair by contaminated fuel.

The fuel injection pump is of a rotary type and is driven by the engine. The pump delivers fuel at high pressure to the

fuel injectors. The high pressure fuel is delivered in `pulses' timed at the correct point in the combustion cycle for each cylinder.

When the fuel injectors receive a pulse of fuel at high pressure they inject atomised fuel into the combustion

chamber.

When the pressure of the fuel at the injector’s falls, the injector snaps shut and any trapped fuel bleeds back to the

fuel tanks via the bleed off fuel lines.

Some fuel flows through the pump at all times to provide internal lubrication and cooling. This fuel bleeds back to

tank via the bleed-off fuel lines.

Training Manual – JCB Eco Max Mechanical Engine. Page 11

SYSTEM FUNCTIONS

Basic description of Engine.

1 Fuel tank

2 Water trap (sedimenter)

3 Lift pump

4 Fuel filter

5 Fuel injection pump (FIP) (DP210 pump shown)

6 Fuel injectors (atomisers)

Colour Key - Fuel Lines

Green -Suction

Yellow -Low pressure

Red -High pressure

Orange -Bleed-off (return to tank)

Cooling System

Training Manual – JCB Eco Max Mechanical Engine. Page 12

SYSTEM FUNCTIONS

Basic description of Engine.

Description

During the working cycle of the engine a great deal of heat is generated. It is important that the engine is kept at its

normal operating temperature to achieve maximum efficiency. It is the function of the cooling system to allow the engine to

reach this temperature quickly and then maintain it.

Coolant pump, driven via a pulley and front end accessory drive belt, draws coolant from the pump cavity.

Coolant is pumped through the outlet gallery to the oil cooler cavity in the left-hand side of the cylinder block. As the

coolant flows past the oil cooler matrix heat is exchanged from the oil to the coolant. This enables the oil to function as a

coolant as well as a lubricant. See Lubrication System.

The coolant leaves the oil cooler cavity and passes into the main cylinder block gallery. The gallery is connected to the

cylinder water jackets. Coolant flows around and up the jackets and then passes into the cylinder head via link galleries. Coolant

circulates around the cylinder head where it conducts heat away from the combustion chambers and also the fuel injector tips.

The coolant then passes to the thermostat housing.

When the engine is below normal operating temperature the thermostat is closed, preventing coolant flowing to the

machine radiator via the top hose connection port. Instead coolant is directed through by-pass gallery back to the pump cavity

and is again drawn into the pump.

When the engine is at operating temperature the thermostat opens, closing the by-pass gallery to the pump and

opening the top hose connection port to the machine radiator. Coolant passes through the radiator matrix and is cooled. The

coolant flows back to the engine via bottom hose connection port and is again drawn into the pump.

A coolant temperature gauge and warning light sender unit is fitted at port.

A cab heater hose can be fitted at port. This enables coolant to circulate through a heater matrix when the

thermostat is open or closed, ensuring fast heater warm up.

A cold start switch is fitted at port. When the coolant is cold the switch closes and energises a cold start solenoid on

the fuel injection pump, enabling a cold start mode.

1 Coolant pump 9 Thermostat housing - cylinder head

2 Drive belt - coolant pump 10 Thermostat - cylinder head

3 Pump cavity - cylinder block 11 Top hose connection port - cylinder head

4 Pump outlet gallery - cylinder block 12 By-pass gallery - cylinder head and block

5 Oil cooler cavity - cylinder block 13 Bottom hose connection port - cylinder block

6 .Coolant gallery - cylinder block 14. Port - Coolant temperature sender and switch unit

7. Cylinder cooling jackets - cylinder block 15. Port - Cab heater hose connection

8. Link galleries - cylinder block to head 16. Port - Cold start switch - cylinder block

Training Manual – JCB Eco Max Mechanical Engine. Page 13

SYSTEM FUNCTIONS

Basic description of Engine.

Induction and Exhaust Systems

The induction system ensures the required volume of air enters the engine to provide efficient combustion of the fuel

in the cylinders. There are 3 types of induction system to suite different engine applications:

– Naturally aspirated

– Turbocharged

– Turbocharged and inter-cooled

Naturally Aspirated

Air is drawn into the engine via the air filter 36-1. The air at atmospheric pressure flows from the air filter to

the inlet manifold, from where it is pulled into the cylinder during the induction cycle. Exhaust gases leave the engine

via exhaust manifold.

Training Manual – JCB Eco Max Mechanical Engine. Page 14

SYSTEM FUNCTIONS

Basic description of Engine.

Component Identification

1 .Air filter

2 .Inlet manifold

3 .Exhaust manifold

Turbocharged

A turbocharger is bolted to the outlet port of the exhaust manifold.

The turbocharger uses energy from the exhaust gases to drive a turbine which in turn drives the compressor via a

common shaft. Air is drawn through the air filter into the compressor side of the turbocharger. The compressor forces

pressurised air into the cylinders via the cross-over pipe and inlet manifold. The extra volume of air allows more fuel to be

injected increasing the engine power output.

The air is compressed to a minimum pressure of 1 bar (14.5 lb/in2) depending upon engine speed and load. The

turbocharger spins at up to 1000,000 rpm and reaches temperatures approaching 700 ºC (1292 ºF); it is essential, therefore,

that a good supply of oil reaches it at all times. The oil not only lubricates the turbocharger but also carries away excess heat.

External oil feed pipe connected to a port on the cylinder block supplies oil to the turbocharger bearing. Oil returns to the

engine oil pan via external drain pipe. Integral oil seals prevent oil escaping to the compressor and turbine ends of the

turbocharger.

The pressure generated by the compressor is known as `boost pressure' The boost pressure is controlled by the

wastegate assembly. Boost pressure acts on a pneumatic actuator. The actuator is linked to the wastegate valve via operating

linkage. When the boost pressure reaches a pre-set value the wastegate opens allowing exhaust gas to bypass the turbine, thus

reducing the speed of the compressor. At higher engine speeds the wastegate is continually opening and closing a small

amount, maintaining a constant boost pressure.

Training Manual – JCB Eco Max Mechanical Engine. Page 15

SYSTEM FUNCTIONS

Basic description of Engine.

Component Identification

1 Turbocharger 2 Exhaust manifold

3 Turbine 4 Compressor

5 Air filter 6 Cross-over pipe

7 Inlet manifold

Intercooled

Turbocharged engines can be configured for inter-cooling. As the air is compressed by the turbocharger it also heats

up and becomes less dense, reducing the combustion efficiency. By passing the compressed air through a heat exchanger or

`inter-cooler' it is cooled before reaching the engine. The inter-cooler most commonly takes the form of an air blast matrix but

can be a water cooled matrix.

Exhaust Gas Recirculation (EGR)

Training Manual – JCB Eco Max Mechanical Engine. Page 16

SYSTEM FUNCTIONS

Basic description of Engine.

The JCB Dieselmax Engine (Mechanical Tier 3) features an internal Exhaust Gas Recirculation (EGR) system. This

enables a small amount of exhaust gas to be introduced into the induction air for combustion.

The system reduces nitrogen oxide (NOx) emissions.

A small amount of exhaust gas is introduced into the inlet manifold by using the camshaft to open the inlet valves

during the exhaust stroke. The valves are opened only for a short period and at low lift.

To achieve this, each of the camshaft inlet lobes A is provided with a second lobe portion B which has a very small

height measurement over and above its basic curve. This is additional to the main inlet valve opening ramp C.

EGR tends to reduce the amount of fuel burned in the power stroke. This is evident by the increase in particulate

emissions that corresponds to an increase in EGR.

Particulate matter (mainly carbon) that is not burned in the power stroke is wasted energy. This increase in

particulate emissions maybe perceived as excessive black smoke although it is perfectly normal.

Training Manual – JCB Eco Max Mechanical Engine. Page 17

FUEL INJECTION PUMP REMOVAL AND FITMENT

Basic description of Engine.

Fuel Injection Pump - Removal and Fitment

Component Identification

1 Fuel injection pump

2 Pump fixing nuts

3 Injection pump gear cover

4 Injection pump lock bolt

5 Keyhole washer

6 Cold start advance solenoid

7 Electric shut-off solenoid (ESOS)

8 Fuel line connector (inlet)

9 Fuel bleed-off connector

10 Turbo boost vacuum pipe (if fitted)

11 Drive shaft nut

12 Drive gear

15 Throttle lever

Training Manual – JCB Eco Max Mechanical Engine. Page 18

FUEL INJECTION PUMP REMOVAL AND FITMENT

Basic description of Engine.

16 Lift Pump

Service Tools

Item Description

A Timing pin – crankshaft

C Crankshaft turning tool

D Top dead centre setting tool

E Gear removal tool

comprises:

F Reaction cap / Blind Nut

G Tool body

H Special bolt

J ‘C’ shaped ring spanner

13 Blanking plug (access for

crankshaft locking pin)

Training Manual – JCB Eco Max Mechanical Engine. Page 19

FUEL INJECTION PUMP REMOVAL AND FITMENT

Basic description of Engine.

Before removing:

a) Ensure that the engine cannot be started.

b) Release the fuel line couplings at the inlet connection 8 and bleed-off connection 9 on the

pump. Remove the high pressure fuel lines.

c) Release the fuel line couplings at the fuel lift pump connections 18 and disconnect the throttle

cable.

IMPORTANT NOTE: DO NOT attempt to remove the fuel injection pump until both the engine and pump

are mechanically locked in the correct position - refer to the procedures below.

Training Manual – JCB Eco Max Mechanical Engine. Page 20

FUEL INJECTION PUMP REMOVAL AND FITMENT

Basic description of Engine.

The pump will need the timing reset by a fuel injection equipment specialist if it is not locked in the

correct position prior to removal.

Removal

1) Uncouple the electrical connectors at the shut-off solenoid (ESOS) 7 and cold advance solenoid

6.

2) Turbocharged Engines Only: Disconnect the boost control vacuum pipe 10 at the diaphragm on

the injection pump.

3) Remove the taper blanking plug 13.

4) Set number 1 piston to top dead center (on its compression stroke):

5) Remove the fuel lift pump.

6) Install the TDC setting tool D, use one of the lift pump retaining bolts 17 to hold the tool in

position.

7) Make sure that the top hole locates centrally over the lift pump actuating pin 19.

8) Use rotation tool B and turn the crankshaft until timing pin A engages in the crankshaft timing

hole. Check that the lift pump actuating pin is protruding from the face of the setting tool, if not

complete steps 4.4 and 4.5.

9) Remove the timing pin A.

10) Rotate the crank pulley 360° and refit the timing pin A

Training Manual – JCB Eco Max Mechanical Engine. Page 21

FUEL INJECTION PUMP REMOVAL AND FITMENT

Basic description of Engine.

Note: The timing pin MUST be engaged in the crankshaft

timing hole. It is possible that the pin may appear to ‘engage’

but it is in fact between the crankshaft webbing.

Always check the pin has engaged correctly by trying to move the crankshaft clockwise and anti-

clockwise. If you can not turn the crankshaft in both directions, the pins will be engaged.

11) Remove fuel injection pump gear cover 3.

12) Undo and remove the drive shaft nut 11.

13) Loosen lock bolt 4 on the fuel injection pump so that the special keyhole washer 5 can be slid

across to its locking position (as shown at Y). Screw the lock bolt in and torque tighten. The

washer 5 should be loose.

Training Manual – JCB Eco Max Mechanical Engine. Page 22

FUEL INJECTION PUMP REMOVAL AND FITMENT

Basic description of Engine.

14) Undo and remove the nuts 2. Use special spanner J to undo the nut close to the cylinder block.

Be sure to remove all 3 nuts.

15) Fit reaction cap F (service tool) over the pump shaft. Screw service tool G to the housing. Using

a suitable ratchet drive and socket screw in bolt H (service tool) until resistance is felt.

16) The injection pump drive gear 12 is located on a taper on the pump drive shaft. To remove the

pump the taper lock must be ‘broken’. Support the fuel injection pump. Tap the end of bolt H

with a soft faced hammer. When the taper ‘breaks’ there will be an audible sound.

Note: The pump drive gear connects to the injection pump drive shaft by means of taper lock

alone. There is no mechanical locking key.

17) Withdraw the pump from the flywheel housing. Remove service tools H, G and F. IMPORTANT

NOTE: DO NOT remove the engine locking pin A. Make sure that no one attempts to turn the

engine.

IMPORTANT NOTE: DO NOT loosen the fuel injection pump lock bolt 4.

Replacement / Fitment

Service procedures on the fuel injection pump can only be carried out by specialist personnel with the

relevant training and equipment. Before replacing an injection pump with a new one, or one that has

been serviced, make sure that the drive shaft is locked, with bolt 4 tightened with keyhole washer 5 in

the correct position. Make sure that the engine is still locked in the correct position.

1) Make sure that taper surfaces on the injection pump drive shaft and gear 12 are clean and free

from oil.

Training Manual – JCB Eco Max Mechanical Engine. Page 23

FUEL INJECTION PUMP REMOVAL AND FITMENT

Basic description of Engine.

2) Make sure that the oil seal is correctly located on the injection pump mounting face. Locate the

pump onto the mounting studs. Locate the drive gear 12 over the pump drive shaft.

3) Fit and torque tighten the nuts 2 to 24 Nm (17.7 lbf ft). Use special spanner H to tighten the nut

close to the cylinder block.

4) Fit and torque tighten the pump gear nut 11 to the 1st stage pre torque.

Note: If the washer is supplied with a replacement pump, DO NOT FIT THE WASHER. Secure the gear

with the nut 11 only.

5) Loosen lock bolt 4 until the keyhole washer 5 can be slid under the bolt (as shown at X). Then

torque tighten bolt 4. The washer 5 should be locked.

6) Torque tighten pump gear nut 11 to final stage.

7) Fit the gear cover 3 using service tool. Make sure its sealing ‘O’ ring is correctly fitted. Torque

tighten the gear cover.

8) Remove the engine lock pin A and refit the blanking plug B.

9) Couple the electrical connectors at the shut-off solenoid(ESOS) 7 and cold advance solenoid 6.

10) Turbocharged Engines Only: Reconnect the boost control vacuum pipe 10 at the diaphragm on

the injection pump.

After replacing:

1) Replace the rocker cover on Cylinder Head .

2) Reconnect the fuel line couplings at the inlet connection 8 and bleed-off connection 9 on the

pump. Fit the high pressure fuel lines.

3) Remove the TDC setting tool and replace the fuel lift pump.

4) Reconnect the throttle cable.

5) Bleed the fuel system.

6) Start the engine and check for fuel leaks.

Training Manual – JCB Eco Max Mechanical Engine. Page 24

VALVE CLEARANCES

Basic description of Engine.

Valve Clearances – Adjustment

Component Identification

1 Rockers

2 Bridge pieces

3 Tappet adjusters

I - Inlet valves

E - Exhaust valves

Training Manual – JCB Eco Max Mechanical Engine. Page 25

VALVE CLEARANCES

Basic description of Engine.

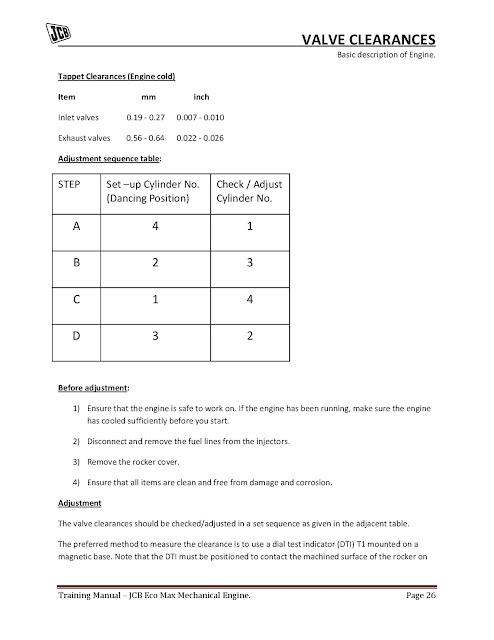

Tappet Clearances (Engine cold)

Item mm inch

Inlet valves 0.19 - 0.27 0.007 - 0.010

Exhaust valves 0.56 - 0.64 0.022 - 0.026

Adjustment sequence table:

STEP Set –up Cylinder No. Check / Adjust

(Dancing Position) Cylinder No.

A 4 1

B 2 3

C 1 4

D 3 2

Before adjustment:

1) Ensure that the engine is safe to work on. If the engine has been running, make sure the engine

has cooled sufficiently before you start.

2) Disconnect and remove the fuel lines from the injectors.

3) Remove the rocker cover.

4) Ensure that all items are clean and free from damage and corrosion.

Adjustment

The valve clearances should be checked/adjusted in a set sequence as given in the adjacent table.

The preferred method to measure the clearance is to use a dial test indicator (DTI) T1 mounted on a

magnetic base. Note that the DTI must be positioned to contact the machined surface of the rocker on

Training Manual – JCB Eco Max Mechanical Engine. Page 26

VALVE CLEARANCES

Basic description of Engine.

the centre line X. If a DTI is not available, feeler gauges can be used to measure the clearance Y between

the bridge piece and the rocker insert as shown.

1) Using a socket and wrench, move the rocker 1 to open the valves against the force of the

springs.

2) Slowly relax the force on the rocker until you feel the exact position at which the valves shut.

Measure the valve clearance from this point.

Step A - Rotate the crankshaft in the normal direction of rotation (clockwise when viewed from the front

of the engine) to ‘set-up’ the valves of No.4 cylinder so that the point is reached where the exhaust

valve is closing while the inlet valve is just starting to open. This is the point where the two

rockers are moving past one another in opposite directions.

With No.4 cylinder in this position, measure the clearance of No.1 cylinder inlet and exhaust valves, and

adjust them if necessary. See Tappet Clearances.

Step B - Further rotate the crankshaft to ‘set-up’ the valves of No.2 cylinder as above, then measure the

clearance of No.3 cylinder valves.

Complete steps c and d in sequence for the remaining cylinders.

Note: Take care to keep the rocker at right angles to the rocker shaft when making measurements,

otherwise incorrect values will be obtained. Always use a socket or ring spanner to turn the tappet

adjusters 3, DO NOT use an open ended spanner.

After adjustment:

1) Replace the rocker cover.

2) Reconnect the fuel lines to the injectors.

Training Manual – JCB Eco Max Mechanical Engine. Page 27

Lubricants and Capacities

Lubricants and Capacities

Engine Lubricating Oil

New engines DO NOT require a running-in period. The

engine/machine should be used in a normal work cycle (1) Not suitable for generator set applications.

immediately, glazing of the piston cylinder bores, resulting

in excessive oil consumption, could occur if the engine is Engine Oil Capacity

gently run-in. Under no circumstances should the engine

be allowed to idle for extended periods; (e.g. warming up Choose the grade of oil to suit the temperature range as

without load). detailed. K Table 54. ( T 1-55). The engine oil capacity,

A minimum API CF4 grade oil must be used. Superior including filter and clean sump is 12 litres MIN and 15 litres

grade oils may be more appropriate for heavy duty MAX mark on the dipstick.

applications (such as sustained high loads and operation Table 56.

at elevated temperatures). Item Capacity litres (UK Gal)

The choice of lubricant viscosity should be made based on Minimum Maximum

the lowest ambient temperature at which the machine will Engine 12 (2.6) 15 (3.3)

be started and the maximum ambient temperature at

which it will operate.

The following table provides guidance as to the

temperature range that can be accommodated by

standard oil viscosities and can be used to select an

appropriate grade. K Table 54. ( T 1-55).

Table 54.

Oil Viscosity Minimum Maximum

Temperature °C (°F) Temperature °C (°F)

SAE 0W30 - 40 (-40) + 30 (86)

SAE 0W20 - 40 (-40) + 10 (50)

SAE 5W20 - 30 (-22) + 10 (50)

SAE 5W40 - 30 (-22) + 40 (104)

SAE 10W30 - 20 (-4) + 40 (104)

SAE 15W40 - 15 (-5) + 50 (122)

Recommended Oils

Table 55.

Engine Oil Specification

JCB High (1)

ACEA E2:B2:A2, API CF4/SG

Performance(1)

JCB Extreme ACEA E5/B3/A3, API CH-4/SJ

Performance

Training Manual - JCB Eco Max Mechanical Engine. Page 28

Lubricants and Capacities

Coolant Mixtures

Coolant Mixtures

!MWARNING

Antifreeze can be harmful. Obey the manufacturer's

instructions when handling full strength or diluted

antifreeze.

7-3-4-4_1

The protection provided by JCB Four Seasons Antifreeze

and Summer Coolant is shown below. If any other anti-

freeze is used, refer to the manufacturer's instructions and

ensure that a corrosion inhibitor is included. DO NOT use

solutions of more than 60% or less than 50% or damage to

the cooling system will occur.

55% Solution - Maintains circulation down to -36 deg C (-

33 deg F), protects against damage down to -41 deg C (-

42 deg F)

The strength of the anti-freeze solution must be checked at

least once a year, preferably at the beginning of the cold

period. It is an advantage to leave the anti-freeze in all the

year round as it gives continued protection against

corrosion. Always renew the anti-freeze every two years. A

50% anti-freeze mixture must be used even if frost

protection is not needed. This gives protection against

corrosion and raises the coolant's boiling point.

It should be noted that serious damage to the cooling

system can occur if corrosion inhibitors are not used.

Training Manual - JCB Eco Max Mechanical Engine. PagePage 02 29

CRANKING TEST

Basic description of Engine.

Cranking test

The cranking test described below needs to be conducted before and after doing any oil and filter

change on all JCB engines. Proceed to carry out the service based on the outcome of cranking test.

1) Start the engine and bring to normal operating temperature which takes about 15 minutes.

2) Disconnect the ESOS electrical connector on the fuel injection pump.

3) Crank the engine for 15 seconds with the ESOS disconnected. Record the time taken by the

engine low oil pressure warning light in the dashboard to go out. The engine low oil pressure

light in the dash board should go out in a maximum of 15 seconds.

4) If the engine oil pressure warning light goes out in less than 15 seconds, reconnect the ESOS and

proceed with the engine service. Ensure the operator fully comprehends the importance of the

low engine oil pressure warning light and the water in fuel warning light.

5) In the rare event that the oil pressure light does not go out in 15 seconds of cranking, stop

cranking and wait for 30 seconds.

6) Crank again for 15 seconds. Again if the oil pressure light does not go out in 15 seconds, abort

the engine service. Do not proceed with the oil and filter change.

Training Manual – JCB Eco Max Mechanical Engine. Page 30

CRANKING TEST

Basic description of Engine.

Training Manual – JCB Eco Max Mechanical Engine. Page 31

INSTRUMENT PANEL

Basic description of Engine.

Instrument Panel indicators:

Engine Oil Pressure Low

Audible / Visual.

Operates if the engine oil pressure is below normal.

The light should go out when the engine is started.

High Engine Coolant Temperature

Red light & audible alarm. Lights if the engine temperature is above normal.

Air Filter Choke

Red light and audible alarm if the air filter is chocked.Water In Fuel Signal comes on when the water level in Pre filter beyond permissible level.

how to use peak pressure gauge

ReplyDeleteAllknowledgefun: Jcb Basic Engine Training Manual 1 >>>>> Download Now

Delete>>>>> Download Full

Allknowledgefun: Jcb Basic Engine Training Manual 1 >>>>> Download LINK

>>>>> Download Now

Allknowledgefun: Jcb Basic Engine Training Manual 1 >>>>> Download Full

>>>>> Download LINK pE

राष्ट्रपति और उससे सम्बंधित महत्वपूर्ण बिन्दु, उसका निर्वाचन , निर्वाचन की विधि , उसका कार्यकाल , योग्यताएं , पद की शर्ते , शपथ , राष्ट्रपति पर महाभियोग ,राष्ट्रपति की शक्तियां

ReplyDeleteकंकाल तंत्र ( Skeleton System ) से सम्बंधित परीक्षा में पूछे गये महत्वपूर्ण प्रश्न

श्वसन तंत्र (Respiratory System) से सम्बंधित परीक्षा में पूछे गये महत्वपूर्ण प्रश्न

उत्सर्जन तंत्र से सम्बंधित परीक्षा में पूछे गये महत्वपूर्ण प्रश्न

राष्ट्रपति और उससे सम्बंधित महत्वपूर्ण बिन्दु, उसका निर्वाचन , निर्वाचन की विधि , उसका कार्यकाल , योग्यताएं , पद की शर्ते , शपथ , राष्ट्रपति पर महाभियोग ,राष्ट्रपति की शक्तियां

ReplyDeleteकंकाल तंत्र ( Skeleton System ) से सम्बंधित परीक्षा में पूछे गये महत्वपूर्ण प्रश्न

श्वसन तंत्र (Respiratory System) से सम्बंधित परीक्षा में पूछे गये महत्वपूर्ण प्रश्न

उत्सर्जन तंत्र से सम्बंधित परीक्षा में पूछे गये महत्वपूर्ण प्रश्न

Good information about the blog. If you are looking for best DMRC (Delhi Metro) Junior Engineer (JEn) coaching classes in Jaipur. Call Us Today at: +919828747676

ReplyDeleteSir how to download the PDF

ReplyDeleteSpark plugs ignite fuel in the engine. SBC 350 Crate Engine

ReplyDeleteCold starts are the biggest challenge for engines. crate engines

ReplyDeleteAffordable and reliable crane rental services. below-the-hook lifting devices

ReplyDelete